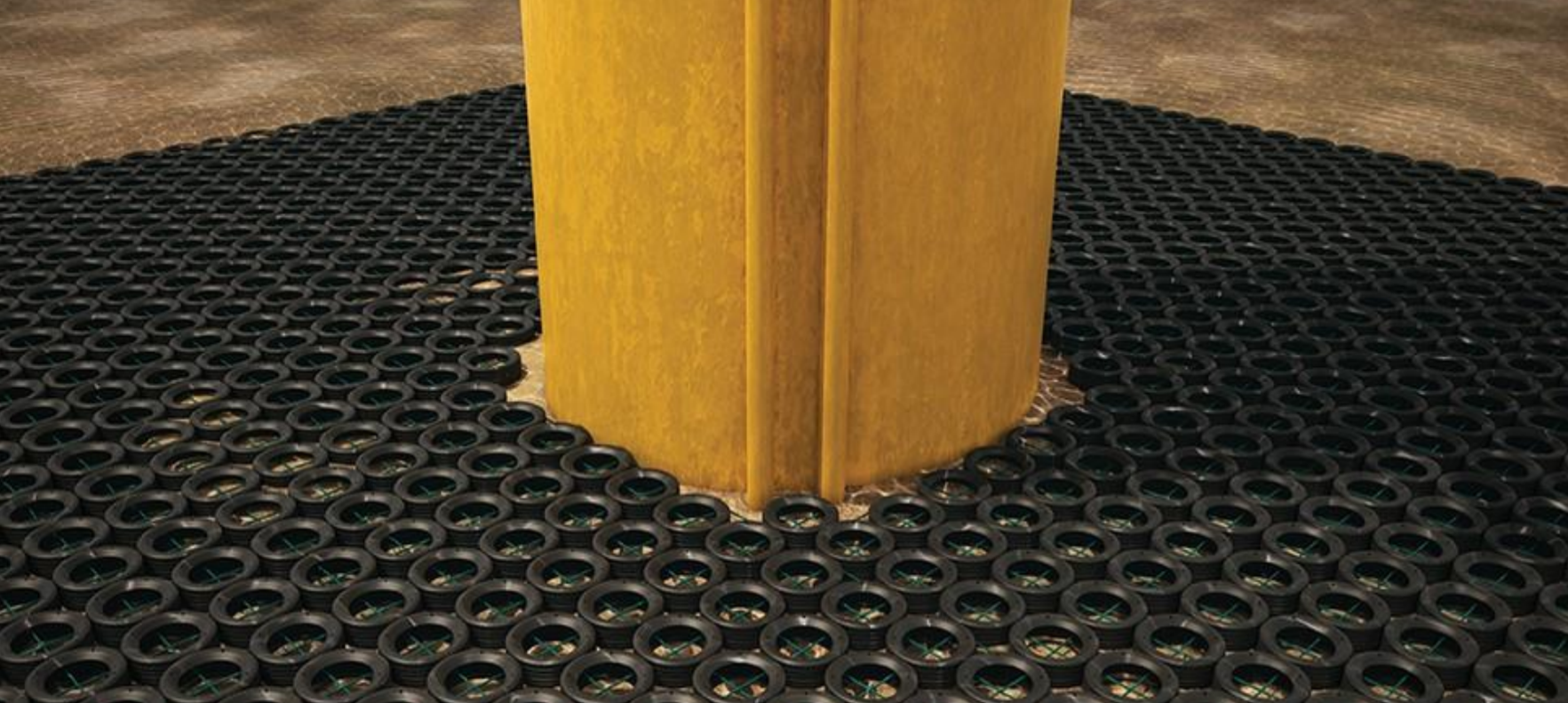

Figure 41 Novel scour protection system visualisation, immediately after installation, courtesy of Scour Prevention Systems.

Function

Scour protection prevents scour of the sea bed caused by the speed-up of water moving around the foundation, which safeguards the performance and integrity of the foundation.

What it costs*

About £5.4 million for a 1 GW wind farm.

Who supplies them

Rock installation firms: Boskalis, DEME, Peter Madsen Rederi and Van Oord Offshore Wind.

Scour mat suppliers: Exo Engineering, Naue, Norfolk Marine and SSCS.

Rock bag suppliers: Ridgeway and Pipeshield.

Key facts

Scour is erosion caused by the presence of a structure changing flow patterns and increasing sediment transport locally around the structure. Scour is therefore an important factor for all foundation types. If sea bed material around the foundation is removed by the action of scour then:

- For a monopile or jacket foundation, the loads from the turbines will be resisted by a shorter embedded length of pile in the sea bed. This will reduce the stiffness of the foundation and will reduce the maximum load the piles can withstand.

- For a gravity base foundation, the foundation could rest on a smaller footprint, which increases the chances of leaning, or in the worst case, toppling.

- For any foundation type, the action of scour will change the frequency response of the structure and may push it into closer to wave or blade driving frequencies, which would amplify loads and accelerate fatigue.

The ground conditions have a consequential impact on the scour assessment and scour protection design. The particle size distribution and the strength are key considerations for both. Non-cohesive sediments (such as sand) do not resist scour whereas cohesive sediments (clay and silt) and bedrock are better able to resist it. Other key factors are waves, currents, water depth and the structure dimensions. All of these need to be considered when estimating scour depths.

In non-cohesive sediments scour depth increases with pile diameter, with design scour depth applied as 1.3 times the diameter of the pile. Scour will therefore be a bigger problem with larger turbines, which require larger diameter piles to transfer loading into the ground.

Depth of non-cohesive sediments is therefore very important in determining accurate scour depths as these inhibit scour.

Jacket structures are expected to be less susceptible to scour due to the smaller diameters of the pile footprint. However, total scour around the foundation also needs to consider the spacing of the vertical legs and lower horizontal members.

The rate of increase in scour depth slows with time until it reaches an equilibrium depth, typically within the first year.

Once an estimate of the scour depth has been calculated, a decision can be made to:

- Design the foundation to cope with the scour estimate including an allowance for the scour depth, or

- Design and install scour protection (which will prevent the scour from occurring).

The additional cost of initial scour protection and repairs over time should be balanced against the cost of designing to cope with the anticipated level of scour. Routine monitoring is required in either scenario to monitor the scour depth development or the effectiveness of scour protection to avoid the risk of movement to the foundations structures.

Crushed rock is most commonly used for scour protection. However, in some cases, rocks can sink into the sediment, and secondary scour around the scour protection can also occur which needs to be considered in the design. Alternatives to rock are available, for example concrete mattresses and geotextile sand containers.

Options for installation of scour protection vary according to design and include pre-pile installation, post installation or a combination of the two.

Scour protection, as well as the turbine structures, become habitats for a number of marine species. However, this may not always be seen as a positive impact as the habitats created are a change to the baseline environment which scour protection was designed for.

What’s in it

- Rock or geotextile sand containers